safe work

RISKY Business

Do you know the importance of reasonably practicable risk management?

Words Chi Nguyen, vegetablesWA RDO

AS A dedicated vegetable grower, the safety of your workers and everyone involved in your farming activities should always be a top priority. It’s not only a moral obligation, but also a legal requirement. Under the guidelines set by the person conducting a business or undertaking (PCBU), you are obligated to do what is ‘reasonably practicable’ to maintain a safe and healthy work environment. In this article, we will explore what ‘reasonably practicable’ means and how you can apply risk management principles to eliminate hazards and control risks effectively. The term ‘reasonably practicable’ is at the heart of workplace safety. Essentially, it means that you should do everything within your means to eliminate risks to health and safety. However, if eliminating a risk is not feasible, you must take measures to minimize it.

Identifying Hazards & Assessing Risks

The first step in managing risks effectively is to identify hazards and assess the associated risks. Hazards in a growing environment can encompass various aspects, from machinery operation to chemical handling. To identify hazards:

• Engage in open communication with your workers and discuss potential risks they may encounter

• Conduct regular workplace inspections to pinpoint any unsafe conditions or practices

• Review previous incidents and near misses to understand past problems and find solutions.

Risk management involves a four-step structured approach to addressing hazards and risks:

1. Identify Hazards Identify all potential risks within your operation.

2. Assess Risk Evaluate the likelihood and severity of possible injuries, deaths, or illnesses resulting from these hazards.

3. Implement Control Measures Determine and implement control measures that will either eliminate or minimise the identified risks.

4. Review Control Measures Continually assess the effectiveness of your control measures and make necessary adjustments.

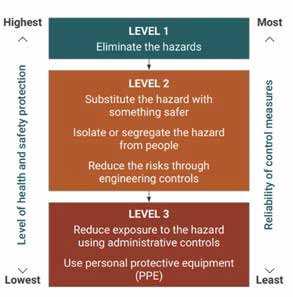

Hierarchy of Control

When it comes to minimising risks, there is a hierarchy of control measures you should follow:

Substitute Whenever possible, replace a hazardous element with something safer. For instance, swapping a dangerous chemical for a less harmful alternative.

Isolate Use barriers or other isolation methods to keep individuals away from the hazard.

Engineering Controls Implement physical control measures, such as machine guards, to reduce risks.

Administrative Controls Use training, checklists, and standard operating procedures to minimise risks.

Personal Protective Equipment (PPE) Provide workers with PPE, such as goggles or safety boots, and educate them on their proper use.

Effective risk management is a collaborative effort. Engage in consultation and cooperation with your workers, health and safety representatives, and any health and safety committee, if applicable, in your workplace. And consult with other stakeholders who share the duty of work health and safety. Finally, ongoing review and assessment of your risk controls are crucial, regularly assessing the effectiveness of current control measures, monitoring changes in risks, addressing new hazards and gathering worker feedback. In the world of vegetable growing, safety is not just a choice; it’s an obligation. Understanding what is ‘reasonably practicable’ and implementing effective risk management measures will not only create a safer, healthier and more productive workplace for everyone involved, but also help ensure the long-term success of your operation.

Risk management in practice

What

Agricultural chemicals: pesticides and herbicides pose risks to workers’ health if not handled properly. Identify potential hazards by assessing the toxicity of the chemicals in use, as well as the likelihood of exposure through mixing, application, and disposal. Evaluate the need for proper storage, labelling and PPE to mitigate the risks associated with chemical exposure. Accidental spills or leaks of agricultural chemicals can lead to soil and water contamination. Evaluate the risk of spills during chemical handling, storage, or transport and establish emergency response plans, and employee training to address these risks.

How

Hierarchy of Control Measures

Substitute: explore alternatives to highly toxic chemicals and use integrated pest management (IPM) strategies that rely less on chemical applications.

Isolate: ensure that chemical storage areas are well-separated from worker areas and equipped with spill containment measures to prevent the spread of chemical spills.

Engineering controls: install proper ventilation systems in chemical mixing areas to reduce inhalation risks.

Administrative controls: develop and implement standard operating procedures for chemical handling, including labelling, storage and disposal guidelines. Conduct regular safety training for workers.

PPE: provide workers with appropriate PPE, such as chemical-resistant gloves, goggles and respiratory protection, and educate them on its proper use.

MORE INFORMATION, visit bit.ly/3v0P2Cv.