VegNET FEATURE

Research to practice

Applying lessons in a biomineral approach to vegetable production across WA

With appropriate support, growers can apply research findings to their unique production systems using field investigations that generate data and observations to inform on-farm practice.

Words Katrina Hill, Regional Development Officer, VegNET

THIS approach has been successful for growers in Carnarvon’s horticulture industry, leading to the adaptation and integration of a biomineral production system into farming practices across a range of fruit and vegetable crops.

The biomineral system replaces inefficient, short-term fertiliser applications with a targeted approach using small doses of a custom microbe blend, controlled-release mineral fertilisers, and supplementary liquids as needed. The microbes extend the plant’s root system, enabling access to otherwise unreachable nutrients and water, and convert unavailable nutrients into plant-available forms. The controlled-release fertilisers nourish both the soil biology and the plant, enhancing overall nutrient efficiency.

The benefits of a biomineral system include:

• Reduced input and production costs.

• Increased profitability.

• Enhanced product quality, driving market demand.

• Extended product shelf life.

• Increased water and nutrient use efficiency.

• Improved soil fertility and health.

Following the success and results achieved by growers in Carnarvon in the north of the state, a VegNET WA input use efficiency project actively shared these insights with the broader vegetable industry, generating significant interest among growers and providing an opportunity to expand knowledge across regions and commodities, including Albany in the south of the state.

Key messages

• VegNET WA worked with a horticultural producer in Albany to evaluate how well sweet corn production knowledge developed in Carnarvon could be adapted to the different climatic and soil conditions of the south coast.

• The sweet corn field investigation was based on the results from a replicated trial at the Carnarvon Research Station, comparing a biomineral production system to conventional fertiliser strategies.

• The Albany trial demonstrated that the biomineral approach could achieve a similar total marketable yield as conventional methods, while producing more consistent growth with lower nutrient inputs.

• Ease of substituting biominerals from water-soluble fertilisers and reduced handling volume.

VegNET WA coordinated a trial of a biomineral fertiliser production system in red cabbage in the south metro.

Field investigation targets sweet corn

The field investigation in Albany adopted a pragmatic approach, employing standard agronomic monitoring practices. The performance of the biomineral system was assessed against the traditional grower practice of using granular, water-soluble fertiliser.

The grower collected soil and leaf tissue samples, made field observations and completed yield assessments.

A soil analysis was used to determine the baseline and post-harvest nutritional status of both treatments, and leaf tissue samples were taken late in the production crop cycle to assess plant nutritional uptake.

Sweet corn crop monitoring and yield assessments were completed by the grower to make appropriate decisions and provide a meaningful assessment.

The conventional treatment (grower’s normal practice) involved applying a fertiliser with a nitrogen, phosphorus and potassium (NPK) analysis of 12:5:15 at a rate of 730 kg/ha.

This was compared with a biomineral fertiliser comprising biological and controlled release mineral components with a NPK analysis of 10:7:4.5, applied at a rate of 500 kg/ha. Both treatments were banded at sowing.

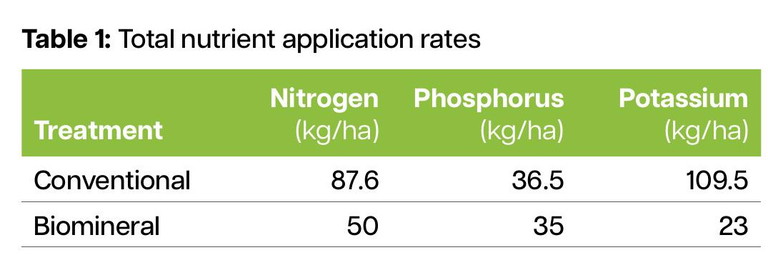

Table 1 summarises the total nutrient application rates of each treatment.

The biomineral program was based on the treatment used in the Carnarvon trial and included the option to apply supplementary nitrogen at a rate of 10 kg/ha at tasselling if a deficiency was observed. However, this was not required.

The conventional treatment had a nitrogen and phosphorus content almost directly proportional to one of the fertiliser strategies in Carnarvon, but a potassium content almost five times higher.

Trial results

Yield

The grower reported comparable yields from both treatments, approximately 16 tonnes/ha. This is considered a respectable yield and aligns closely with the results from the Carnarvon trial.

Soil and plant nutrition

Despite the lower application rates of the biomineral program, neither treatment displayed nutrient deficiencies during any growth phases. This was shown by leaf tissue analysis conducted late in the crop cycle indicating that both strategies fulfilled plant nutritional requirements, despite differences in nitrogen and potassium application rates.

Post-harvest soil analysis revealed that no nutrients were depleted below acceptable levels in either treatment.

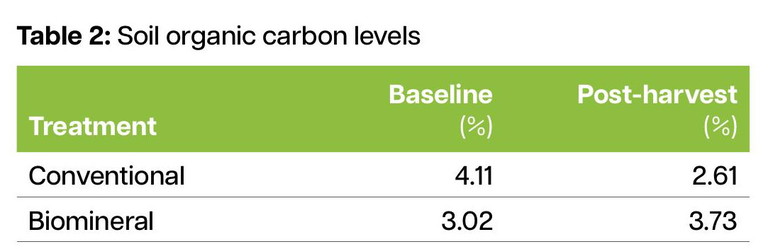

Interestingly, the biomineral treatment led to a significant increase in soil organic carbon levels, whereas a marked decline was observed in the conventional treatment (Table 2).

The trial showed high correlation between Carnarvon and Albany treatments, except for potassium rates, highlighting translation of controlled setting results to field outcomes with consistent yield.

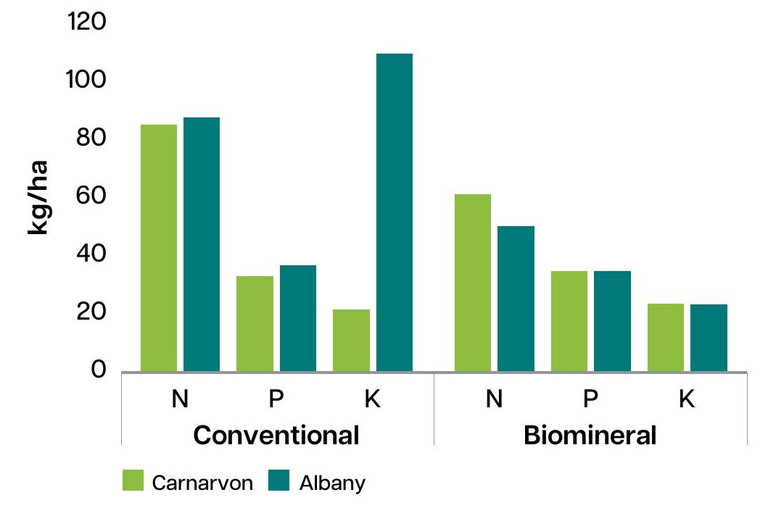

Figure 1 compares the application rates of the two treatments in Carnarvon and Albany.

Yield responses

The results recorded in Albany strongly reflect those of the replicated trial at Carnarvon, despite the higher potassium content of the conventional treatment and the slightly reduced nitrogen in the biomineral treatment applied in Albany.

Nutrient use efficiency

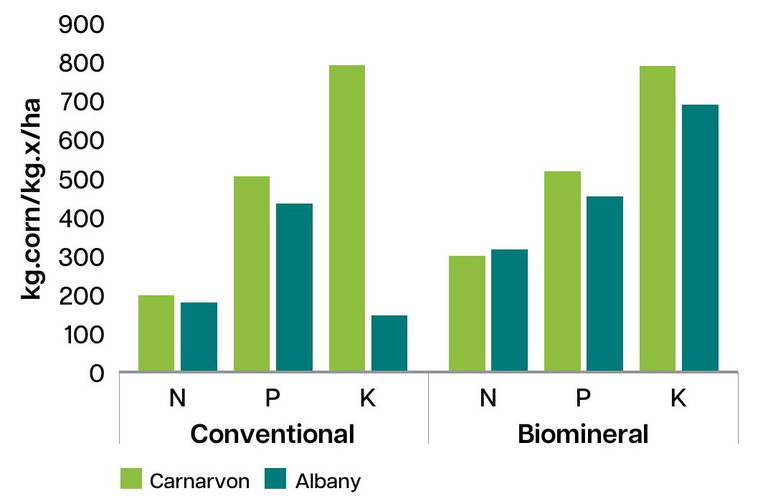

The biomineral treatment resulted in a significantly higher nitrogen use efficiency (>30 percent) at both Carnarvon and Albany, compared to the conventional treatments. This can be attributed to the controlled release format of the biomineral fertiliser formulation which introduced free-living nitrogen fixing bacteria.

The phosphorus application rates were similar in both treatments and able to fulfil crop requirements. It was observed that soil available phosphorus declined slightly under the biomineral treatment, while it increased substantially under the conventional treatment. This suggests that crop in the biomineral treatment was more effective in using the phosphorus supplied by the program in addition to what was available in the soil, demonstrating reduced risk of loss from the site when compared with the conventional treatment.

The excess potassium applied in the conventional treatment at Albany did not result in a yield response and therefore substantially lowered the efficiency of potassium use, especially when compared to the biomineral treatments at both sites and the conventional treatment in Carnarvon.

Figure 2 provides a comparative analysis of nutrient use efficiency for each treatment at Carnarvon and Albany.

These results are consistent with the outcomes of the Carnarvon trial, demonstrating the potential efficiency gains in nutrient usage with the biomineral method and providing another perspective for the grower to consider when choosing a fertiliser strategy for nutrient use efficiency.

Soil organic carbon

The two treatments produced significantly different results for soil organic carbon levels.

Post-harvest soil test results showed these levels increased substantially following the biomineral treatment. This increase equates to an additional 10 t/ha of soil organic carbon being present in the top 10 cm of soil. This enables the soil to store an additional 40 kL/ha of water and approximately 55 kg/ha more organic nitrogen, potentially enhancing the water and nutrient use efficiency for successive crops.

Conversely, the conventional treatment resulted in a significant decrease in soil organic carbon content, by almost 40 per cent. This depletion in carbon content reduces the soil’s water holding capacity by 84 kL/ha and could deplete the soil organic nitrogen pool by up to 220 kg/ha.

This depletion could have major implications for subsequent crops, potentially affecting water and nutrient use efficiency and profitability.

FIGURE 1: Comparison of nutrient application rates in Carnarvon and Albany

FIGURE 2: Nutrient use efficiency comparison

Economic assessment

The conventional treatment, despite its lower cost per tonne to apply, led to reduced nutrient use efficiency and negatively affected profitability due to the higher volume of fertiliser needed to achieve the same yield as the biomineral treatment.

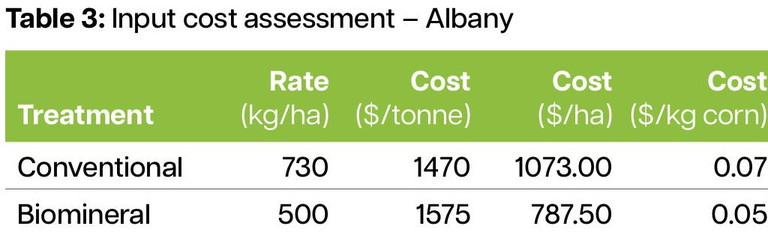

Table 3 provides a detailed input cost assessment for each treatment.

The differences in input costs between these two fertiliser strategies can have implications for the economic performance of an enterprise.

Given the promising operational efficiency demonstrated by the biomineral treatment in both Albany and Carnarvon, it presents a strategic opportunity for growers to increase their profitability by reducing operating costs while maintaining the same level of income.

Improving grower productivity, profitability, preparedness and competitiveness

The results from this field investigation in Albany confirm the findings of the replicated trial in Carnarvon and aligns with production performances observed by other growers. It is consistent with results from published research in the broadacre agricultural industry and an example of how research conducted in other locations and industries is relevant to local conditions, how it can be adapted and integrated into different production systems.

The differences in soil organic carbon levels at the conclusion of the investigation highlights the capacity of the biomineral approach to improve soil health, nutrition and water holding capacity; support growers to adapt to shifting consumer expectations and bolster their environmental credentials; and enhance the economic performance of their business.

Although there was no difference in marketable yield between the two fertiliser strategies, the grower observed more consistent growth under the biomineral program, reduced handling volume and ease of substituting biominerals from water-soluble fertilisers, adding to the program’s efficiency.

Based on the results from this field investigation and the research in Carnarvon, the Albany grower has decided to transition their operation to the biomineral production system.

This field investigation serves as both a proof of concept of research results and how they can translate into a practice change in the field.

Next steps

Following a promising initial trial in red cabbage, a second trial is planned for kale, allowing the business to further assess the system’s suitability for their mixed crop farm in the Perth metro region.

The VegNET WA input use efficiency project is extending opportunities for vegetable growers across commodities and regions to trial the biomineral production system through a supported practice change model.

MORE INFORMATION

Contact VegNET WA Regional Development Officer Katrina Hill at katrina.hill@vegetableswa.com.au or 0427 373 037.

Horticulture Innovation Australia Limited (Hort Innovation) and VegNET WA make no representations and expressly disclaims all warranties (to the extent permitted by law) about the accuracy, completeness, or currency of information in this case study. Users of this material should take independent action before relying on it’s accuracy in any way.

Reliance on any information provided by Hort Innovation and VegNET WA is entirely at your own risk. Hort Innovation and VegNET WA are not responsible for, and will not be liable for, any loss, damage, claim, expense, cost (including legal costs) or other liability arising in any way (including from Hort Innovation, VegNET WA or any other person’s negligence or otherwise) from your use or non-use of information fin this case study, or from reliance on information contained in this material or that Hort Innovation and VegNET WA provides to you by any other means.