High-speed 3D scanner to inspect fresh produce

THE AVAILABILITY OF a skilled workforce to undertake quality produce inspection in the agri and food industry is rapidly decreasing.

As a result, there is a growing need to automate tasks such as the colour and size assessments of fruit, vegetables and processed food for sorting purposes or to classify batches.

Automation could also lead to work being completed faster, more objectively, more precisely and 24/7 if necessary.

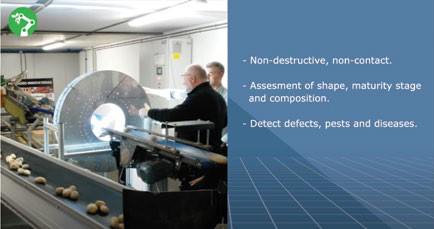

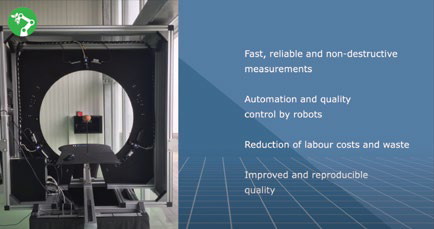

The Wageningen University & Research, located in the Netherlands, has developed a high-speed 3D scanner, designed to help growers, traders, packers, transporters, objectively assess the quality of their products as far as size and shape are concerned.

The scanner, which features a 360-degrees ring-scan, is a precision instrument developed to objectively measure and analyse the size and shape of agri- and food products in all parts of the production chain from harvest to retail.

The high-speed scanning (up to about 20km/h) means the scanner can handle a complete batch of produce instead of just a sample, which is a big advantage compared with other scanning equipment.

It is equipped with a ring of three (or more) line-scan cameras, and a powerful software package to capture images, as well as measuring size and shape in an objective way.

The software has multiple analysis possibilities to measure length, largest diameter, volume, detect spots on products.

MORE INFORMATION

To learn about availability please contact Wageningen University & Research.

Website: www.agrofoodrobotics.eu Email: paul.goethals@wur.nl Youtube: www.youtube.com/c/

AgroFoodRobotics